Product series

Laser welding machine

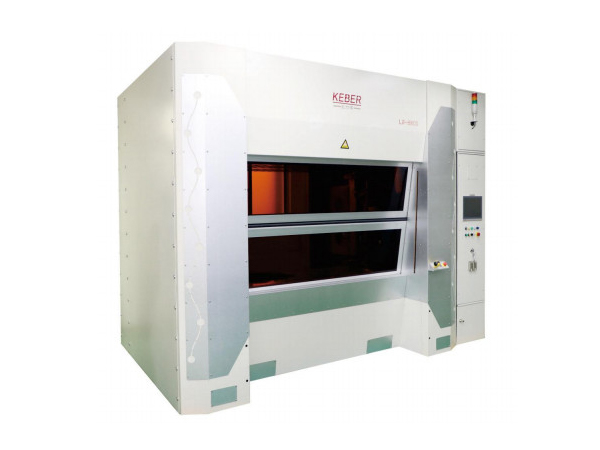

LW-8800 synchronous laser welding machine

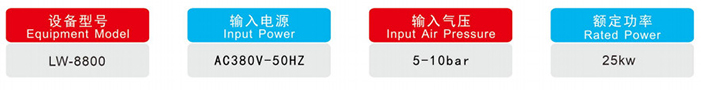

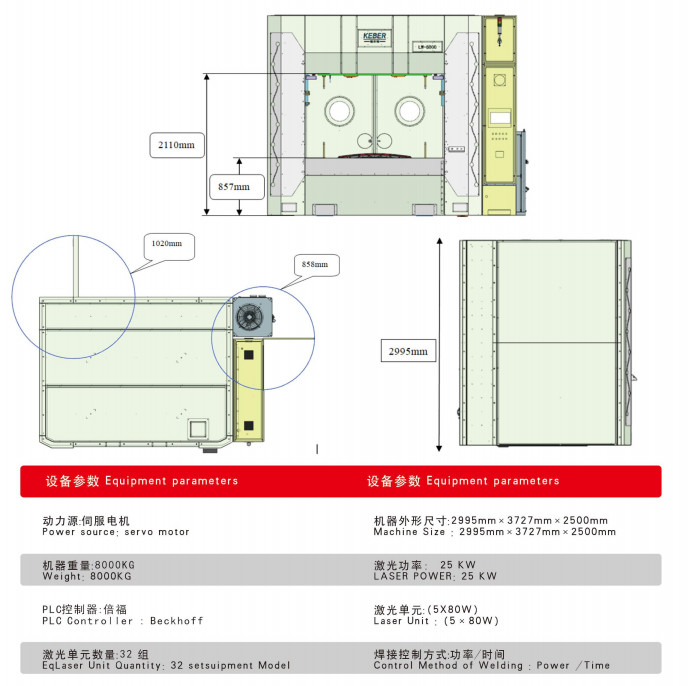

LW-8800 synchronous laser weldinge quipment uses high- power semiconductor laser as its welding lightsource , which has the advantages offast welding time, low thermal effect and low welding therma I stress, effectively improving production efficiency and welding quality.

Function:

●Use 980nm semiconductor laser unit with high power;

●Including 32 sets of synchrotron radiation lighttsource;

●Power and light emission of each welding area can be adjust according to the needs;

●In order to save installation space,integrated water cooling structure is used;

●Equipment has the function of automatic tool change, automatic tool locking and identifythe serial number and version of nesting automatically.

●Support 1.4-meter through-type taillights and fixed-side taillights for one-out two-out welding

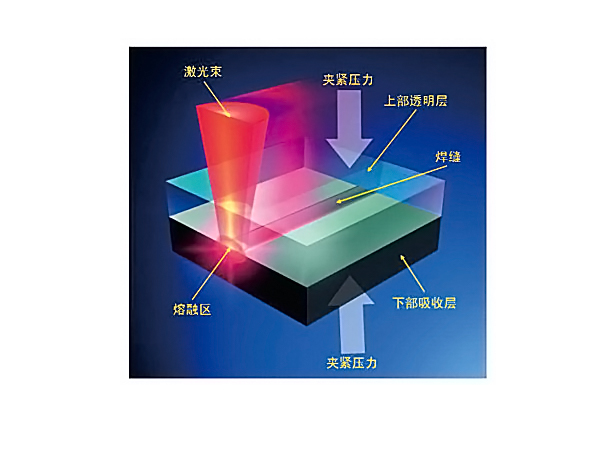

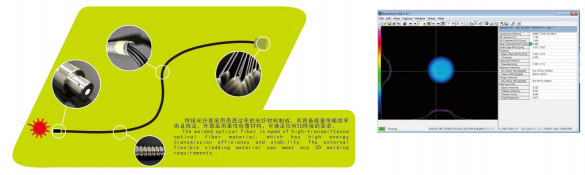

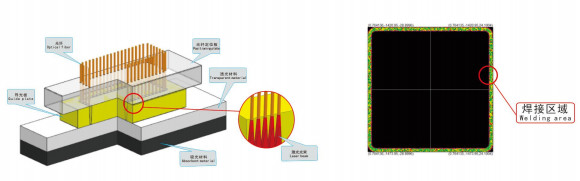

Plastic synchrotron laser transmission welding is to press the plastic parts of the upper layer thr ough near-infrared band and the plastic parts of the I ower absorption layer together. through theI aser beam energy melting of the lower side material,I under the action of pressure and quickly solidified with the upper material; Plastic synchronous laser welding has the advantages of fast we lding speed, small thermal stress, small welding deformation, no vibration, dust and high temperature in the we Iding process, suitable for automobile, 3C e lectronics and medical industr ies.

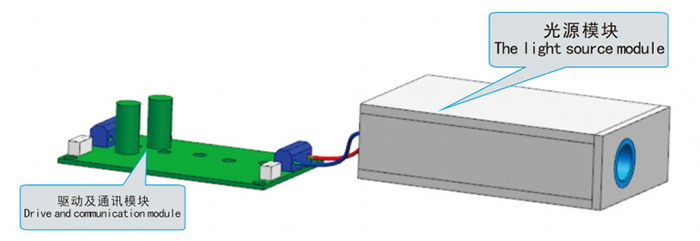

The system adopts the near- infrared band semi conductor laser I ight source, whose wave length is 980nm. The optical path and control system adopt the water-cooled mode. We carried on the r igorous examination test to the whole system, greatly improved the tolerance degree and the high stability of the system.

In the design, the outgoing beam is homogenized, and the spot has obvious flat- top distr ibution and good uni formity, which is suitable for laser welding of plastics.

Used to support the welding are used for optica | structure design of optical fiber or ientation and the wedge of light guide plate structure,which is strictly in accordance with our size the positioning of the optical fiber welding efficiency and the uniformity of the energies of the beams test results perform the design, structure design of guide plate to a great extent improve the eff ici ency of welding, us ing the char acter istics of synchronous we lding way is as foll ows:

1. The design of the uniform distr ibut ion of each fiber combined with the light guide plate gives the flexibility of 3D welding. The fiber can be freely distr ibuted according to the copy surface of the product to be welded, and the welding stability can be guar anteed;

2. The design of light guide plate great ly improves the we lding effici ency. Under the condit ion of ensur ing good tr ansmittance, the welding duration is general ly about 3-6 seconds;

3. The energy concentrated on the welding line can instantaneously melt the underside materials, which can greatly reduce the thermal deformat ion and internal stress of the wel ded products when compared with traditiona I welding;

4. Each light source is separately controlled, and the power and light time can be separately controlled according to debugging requi rements.

Keber Precision Machinery Co.,Ltd

Add:Keber Industrial Park, Dongshan Road,

Linhu Town,Wuzhong District,Suzhou, Jiangsu,China

Tel:+86-512-69011006

Fax:+86-0512-68091510

E-mail:spring@keber.com.cn

http:www.keber.cn